Hydraulic Brake - Handbrake Hydraulic Brake - Handbrake

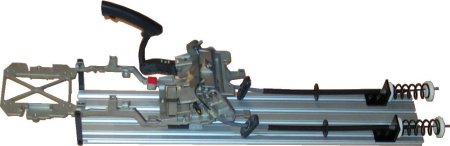

Despite the extravagant specimen above we start with the picture below quite simple. Two cables connect the rear brake drums to the handbrake lever. Rarely could it be the front brake drums or even discs. On the

handbrake lever there is a certain balancing connector between possibly slightly different lengths.

It can be also a single cable from one to the other wheel brake, which runs at the connection to the handbrake lever on a tab, which allows even more compensation for possibly skewed distribution. In the case of a

repair, it is most sensible to replace the entire cable system because it is very sensitive to skewing even during partial braking.

Yes, a handbrake is not only fully activated or released. You also have to consider their function as an emergency brake. While the main inspection allows more difference between left and right, more than 50 percent

should not be allowed here either. The cause may be a cable that does not slide well, but also a problem with the wheel brake itself.

After the introduction of the disc brake, the drums held behind quite a while because of the handbrake and the better self-amplification there (see drum brake). After all, the function as a holding brake on an 18 percent

incline is stipulated by law and may be checked during the main inspection.

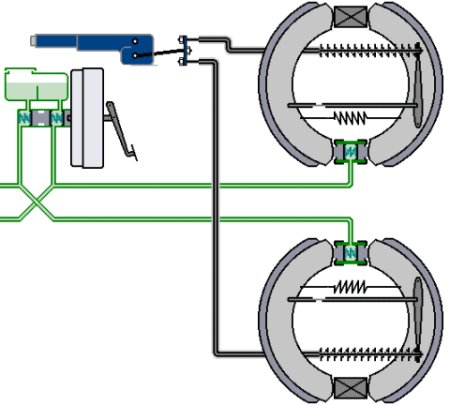

Here you can see where the cable is connected to the drum brake and in which direction it is pulled. With a long lever arm to the cable point of force application and as little as possible to the two brake shoes

connecting spread lever both brake shoes are pressed against the brake drum. On the spread lever even you see an automatic adjuster, which is also explained in the chapter 'Drum Brake'.

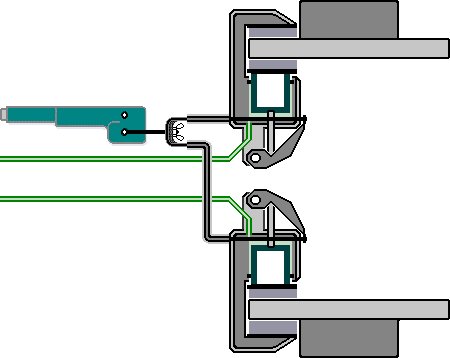

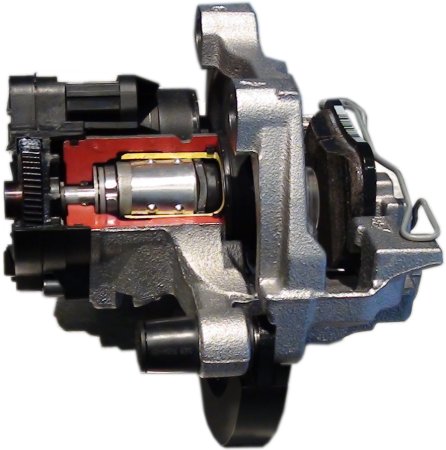

The effect of the cables on a disc brake: Force is applied to a short plunger via a lever mounted on the brake caliper, which acts on the only existing piston (caliper brake).

The plunger is not directly connected to the piston, but via a special adjusting device. You have to imagine this as a screw with ball bearing (!) washer and sleeve. If it is unscrewed from the sleeve, the handbrake

clearance is reduced. When changing the brake pads, it must then be completely screwed back into it. That is the reason why the piston at the rear has to be screwed in and at the front only pushed in.

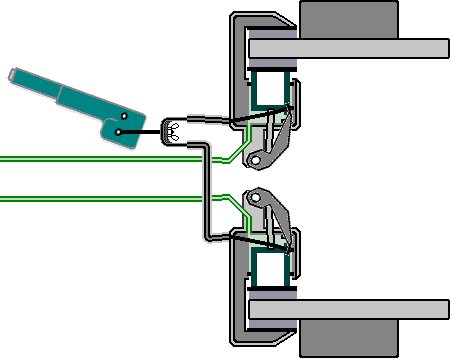

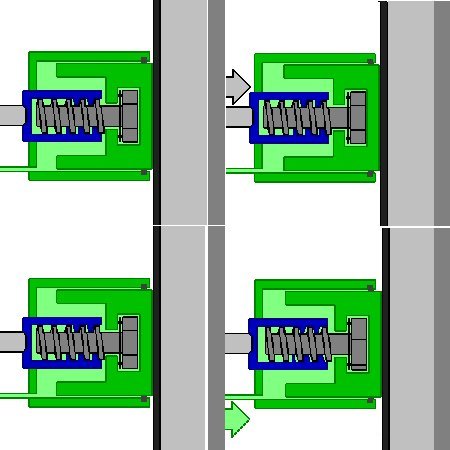

In the picture above you see first on the left the operation by the handbrake outgoing from a normal position and at the bottom the same operation by the footbrake. If the play of the plunger to the piston is too great here,

the particularly smooth screw is automatically twisted slightly when the foot brake is actuated, thereby adapting the play.

| A disassembled brake cylinder . . . |

Below then again the complete brake caliper. At the top right, the handbrake cable is hung. Without the cable, the lever here is on stop. In the case of actuation, it would be pulled back against the spring force and turn

the shaft whose screw we still see on the right. As a result, the plunger is moved toward the pad on the piston. With the movement of the saddle, then also the other brake pad is operated.

And below it is now in the direction of more easy use. The cables are no longer reaching the center console, but only a servomotor. There is no longer a handbrake lever. This creates space, but breaks with cherished

habits. You could not slow down sensitively now either. This will hopefully be fixed by the system, preventing wheel locks and stop the car as fast as possible.

Further down the ropes have been completely eliminated. The electric drive unit is integrated in the brake calliper. A large transmission ratio multiplies the power of the electric motor, although it still works with 12 volts.

We are talking about an electromechanical parking brake.

Where electronics are in it, certain problems begin. Not only that you can not change the brake pads without proper preparation now, also the release of the brake in emergency cases is a problem. Although the system

sets the brake even when the ignition is off, for example, the cooling brake, but you can solve them only with the ignition switched on. This even goes so far that you do not have to operate the parking brake, because it is

locked even with the ignition off.

| Quite compatible with conventional hydraulics . . . |

You probably suspect the effort, if this is not possible for any reason. Sometimes there is supposed a blocking brake and it is actually the automatic transmission. There are even manufacturers in which a mechanical

release of the parking brake in emergencies is possible.

Incidentally, should the vehicle have been parked at a level oblique than 30°, issued by the system a warning that here the function can no longer be ensured. Also, the wear indicator integrated in the pads is no longer

necessary because the system uses a Hall sensor to know how far the electirc motor has traveled to bring the brake pads to a stop. Also, the reset of the brake pads may now no longer be carried out by hand.

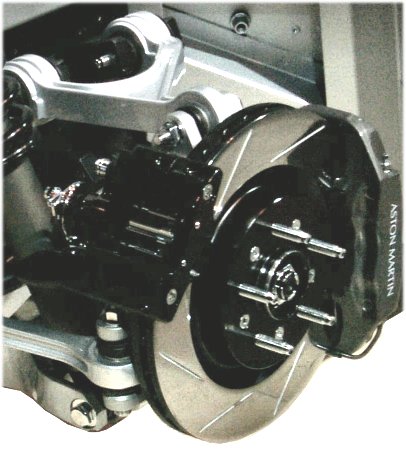

Manufacturers of super sports cars such as Aston Martin are probably not satisfied with the effect of the combined brake. They accept increased unsprung masses in order to install a second caliper with a pair of pads

(in the foreground) on the brake disc only for the parking brake. What this looks like in a clever combination of disc and drum brake, you will find in the chapter 'Drum Brake'.

|