Hydraulische Bremse - Brake Disks Hydraulische Bremse - Brake Disks

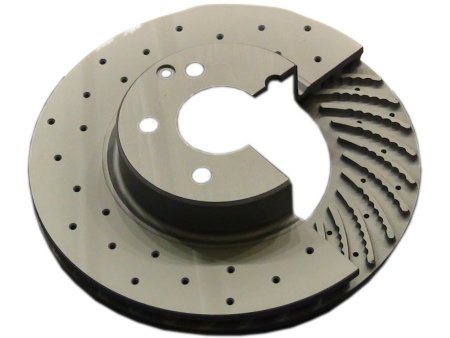

The first example (picture above) already shows that a brake disk does not necessarily have to be a one-piece, but in the meantime it is very often necessary to distinguish between a pot and the actual disk (picture

below). The former can be made of aluminium, the latter not yet. If you only think of the sliding properties of aluminium and consider that brake disks can become red hot, aluminium with its significantly lower melting

point is unsuitable.

| Water-repellent slits/grooves |

Brake disks are made of grey cast iron or steel, but unfortunately the unsprung masses are also loaded. Attempts to move the disks at least at the drive axle inwards to the sprung masses have failed relatively

miserably. With the increasing number of four-wheel drive vehicles, we would have such a possibility at the front and rear.

In racing and sports cars, often for an extra charge, there are ceramic disks that are much lighter. But the prices are still close to those of the cheapest new cars on the market. You have to differentiate between them

according to their intended use, because in Formula 1 they are much more exhausted than in production cars, where the ceramic disks last 300,000 km even under high stress and the brake pads withstand then

approx. 80,000 km long.

No, the pot and washer do not necessarily have to be firmly screwed together. If we take a metal model, the shape of the integrated pot expands less favourably than that of one without a connection. It cannot therefore

be a form-fit connection, especially in the truck sector. Here is an example:

The ventilation of the brake disk should not go unmentioned, which can be found on the cheapest small car as well as on the super expensive ceramic brakes. On the model below you can see how well the direction of

rotation of the wheel is used for the flow. Rear disk brakes are installed throughout, except in small cars, but they are mostly solid.

Overheating of the wheel brake must be avoided at all costs. With simple disks made of GG there is a risk of distortion, which can also result in slight vibrations in the brake pedal. It becomes critical with

crack formation on the disk itself. A possible vapour bubble formation of the residual moisture in the brake fluid is absolutely undesirable.

| Rounded drill hole edges for less lining wear. |

The hardness of the materials is generally chosen so that the linings generally wear more than the disks. If less than half of the ablatable material thickness specified by the manufacturer is used up and the surface is

reasonably smooth, a simple lining change is sufficient.

Filigree, the brake disks on motorcycles and bicycles. Two at the front and one at the rear make it clear how much the weight shift to the front has an effect when braking, so the rear brake becomes almost completely ineffective.

Interesting also the different diameters related to the running direction of the legs pistons (picture below).

|