Hydraulic Brake - Pipes Hydraulic Brake - Pipes

They are divided into rigid metal pipes made of galvanised steel or a copper-nickel alloy and flexible, reinforced hoses. The latter are necessary because the brake fluid has to be transferred from sprung to

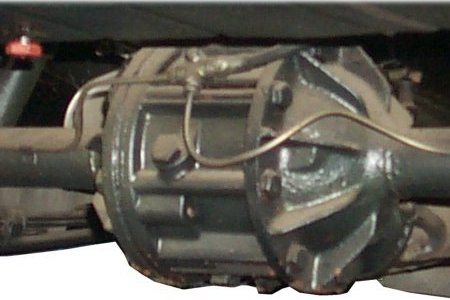

unsprung vehicle areas. Four hoses are therefore usually required for four wheels. A small advantage of the rigid axle is that a hose usually leads from the main line system to a distribution with fixed lines on the axle

itself. With a diagonal division of the dual-circuit brake, this would also be different for the rigid axle.

| On rigid axles, always install on the rear side. |

Since brake hoses still have a high rubber content, even if they are protected externally by flexible metal (steel flex), they should be given increased attention during maintenance. Cracks or chafe marks are clear

warning signs. Their transitions to the fixed pipe system can be plagued by leaks. Perhaps they should generally be completely replaced after ten years, for example.

Abrasions occur when a hose touches parts during deflection or steering, as a result, it wears slowly. So you should at least think about a possible contact perhaps during deflection when you check them and also

carry out the steering practically. Sometimes the hose may touch, but is protected by a thickening at the point.

Almost as bad is a wrong installation of hoses. It can happen that they are twisted between their fittings when the connecting threads are tightened. In principle, however, the assembly should be carried out in such a

way that the hose does not look any different than when dismantled.

What is often overlooked, e.g. in classic cars, is a possible blockage of brake hoses due to rubber material that has been loosened over time. Such material allows the (decisive) pressure of the brake pedal to pass

through, but causes problems when releasing the respective wheel brake. Occasionally, if you are without a driver behind you, let your vehicle roll out particularly slowly without applying the brake. If this ends with a small

jolt, you will have to check it.

This tool is particularly suitable for mounting brake lines because it exerts pressure on the union nut with more than two corners. As a rule, they are already older and can be easily demolished with a simple spanner. It

is best to use this 'slotted ring spanner' right from the start and not after damage has been done to the spanner.

Brake pipes

Outside 4.5 mm and inside 2.5 mm diameter

|

You shouldn't work on a screw connection for too long anyway, then you'd better replace both parts beyond this problem. The pipes in the brake system are made of steel. Sanding to control possible corrosion as in

earlier times is no longer necessary today because they are coated with zinc or plastic.

kfz-tech.de/P57

This is a somewhat more professional set for the production of exactly fitting brake lines, because the original lines are not always still available. Until some time ago, flanging was a compulsory part of training.

Reasonable bends and above all the standardized ends are hardly producible without suitable tools. On an oldtimer, the standard of the flanges should always be ensured before such work.

Please note that the old pipe can still serve as a template. It is hardly necessary to stress that the union nuts have to be pushed on before the last flanging. They also differ depending on the standard, the country and

thus the flanging. The mounting of a tailor-made brake line should not be a problem, except for long pieces and narrow passages.

|