Transmission - Classic US Truck 2 Transmission - Classic US Truck 2

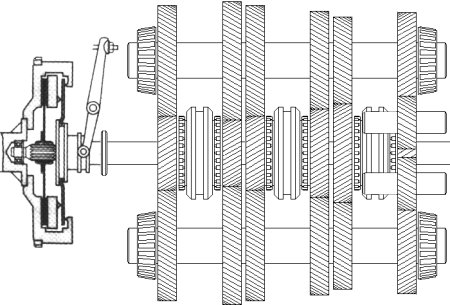

That would now be the principle of the Fuller basic transmission, which fits the shifting scheme in the previous chapter. Of course, the range selector and the splitter are missing, which is why we see the gears Lo, 1, 2, 3, 4

and the fifth as a direct gear after the reverse gear on the far right. On the left then the constant connection to the two layshafts.

A pulled version of the clutch is then shown on the far left. That's what this unsynchronized transmission is all about. It is important to be careful. Three parameters need to be considered: the driving speed, the engine speed

and of course the two gears between which you want to change.

Let's start with the upshift. The pure teaching says that after accelerating in a certain gear, one should depress the clutch, shift out of gear and wait a moment. This continues until the falling engine speed has brought the two

gears now to be connected to approximately the same speed. Then you can step on the clutch again and engage the higher gear.

When shifting down, a double-clutch burst of gas is required after the first engaging the clutch in order to bring the engine up to the higher speed it will have in the next lower gear. And then once more engaging the clutch and

hopefully noiselessly in with it. And how much gas is needed? The tachometer actually tells you that, but also pay attention to the speedometer. If the vehicle speeds up during the shift break because the engine had a certain

braking effect when driving downhill, you have to accelerate a little more, if you go uphill, then less.

So, and now let's look at the clutch again and discover a relatively inconspicuously drawn transmission brake to the right of the release bearing. It can be built in here or elsewhere in the clutch. Importantly, when actuated, it

essentially connects the transmission's input shaft to the housing. It must therefore be firmly connected to the transmission shaft in the picture above.

Such an American clutch has three positions, which is unusual for us Europeans. After a certain distance from the rest position, the usual separation of engine and transmission takes place. However, if you push it further to

its end position, the non-rotatable part of the release bearing in the sketch above reaches the disc rotating with the transmission shaft. Of course, in practice there is still a friction lining in between.

So if a truck is at the traffic light, the clutch is fully depressed in order to stop the transmission shaft(s) that may still be rotating. If the traffic light turns green, you can normally release the clutch in a lower gear and the truck

will drive away. What you should not do, however, is press the clutch all the way down the next time you change gears, but stop about 25 mm (1 inch) beforehand, otherwise the transmission brake will suffer unnecessarily

and there will almost certainly be a loud noise.

|