Carburetor 3 Carburetor 3

Still in the 80s of the last century, the carburetor was just as widespread as the petrol engine is today. The change that we are currently experiencing towards electric cars was towards petrol injection at the time. Like the

electric car today, the has existed for a very long time, but nobody could have imagined in the 80s how quickly the carburettor would disappear from the many millions of cars and, for example, bring the Pierburg company to

the brink of bankruptcy.

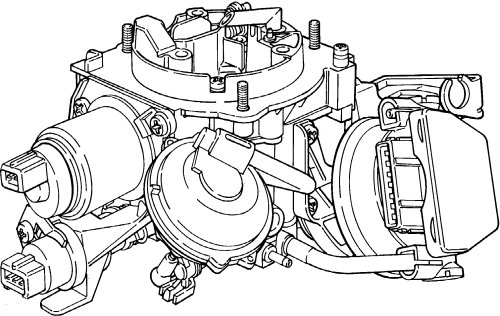

Above the ECOTRONIC carburetor, similar to today's plug-in hybrids, an attempt to retain the carburetor for the combustion engine. It is a conversion of the register carburetor that can react to signals from the lambda probe,

i.e. has the ability to maintain the mixing ratio of lambda = 1 required by the three-way catalytic converter. It was swept away as well as the entire carburetor technology. We briefly trace its development.

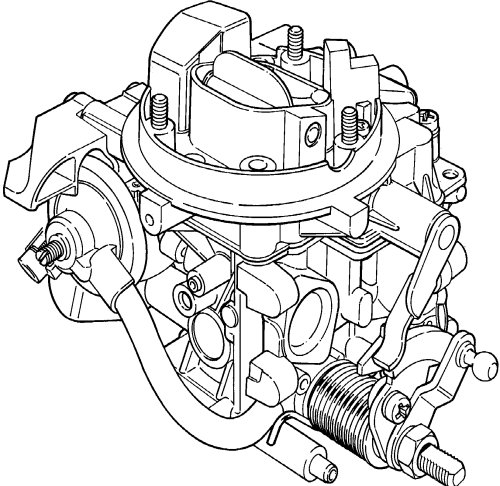

Here, so to speak, the basic level. There is room in the book on automotive technology for a detailed description; here is just an overview. In the middle of the air funnel with the throttle flap below and the choke flap operated

by the automatic starter at the top. If it is completely closed and the throttle valve is slightly open, then this is the preparation for the cold start. The air supply from the air filter is throttled and that of the fuel is increased

because of the negative pressure that forms.

On the left, the inlet to the float chamber, regulated by a valve, with the nozzle system shown folded in here. On the left, the inlet to the float chamber, regulated by a valve, with the nozzle system shown folded in here. The rest

on the left is almost entirely part of the idling system, its complexity is due to the emerging emission regulations. At the bottom left, the enforced shutdown when the ignition is off by a solenoid valve.

We're almost done with that now, only the accelerator pump on the right with every pressure on the gas pedal. The only time that a carburetor mutated into an injector. Even today, it is still not possible to accelerate a

combustion engine without enrichment. Of course there are other single carburetors, especially for two-wheelers, but with this one we have at least largely covered its principle in passenger cars, apart from the constant-

pressure carburetor in the previous chapter, of course.

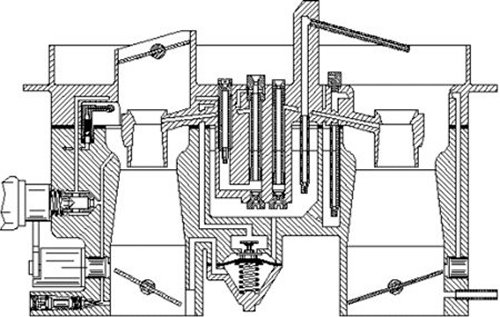

This brings us to the carburetors with more than one air funnel, a maximum of three. We remain with two air funnels and distinguish between double carburetors with separate supply of cylinders through the two and register

carburetors with a combination of the two in the intake manifold. Both air funnels supplied all or at least half of the engine cylinders.

We will stay with the register carburetor because it leads us directly to the ECOTRONIC carburetor shown at the top. In contrast to the double carburetor, the air funnels are very often of different sizes and not all additional

equipment is available for both. One speaks of a first and second stage. You often noticed that in the gas pedal, so you knew when it would get a little more expensive in terms of fuel.

One could also speak of a small carburetor of stage 1 and a switchable of stage 2. It opened the throttle valve of stage 1 with little accelerator pedal travel and stage 2 with more, either linkage or vacuum-controlled. As with

the double carburetor, the float chamber is located between the two air funnels.

Of course, this carburetor worked with a fixed air funnel and thus a clearly defined air-fuel ratio for every operating range. It was trimmed for economy in such a way that it was lean in the partial load range and was only greatly

enriched at full load in order, as has often been said, to achieve the catalog performance. But the former was over now.

A variable mixing ratio determined by the control unit in relation to the lambda probe was required. The engineers have reconstructed the register carburettor, which is clearly visible. The starter flap received a servo motor

indicated here by dashed lines. Now called pre-throttle, it could change the mixing ratio in any operating condition.

The flap was not sensitive enough for idling. Once again it turned out to be the biggest construction site towards cleaner exhaust gases. If you look closely, you'll see a connection to the needle jet that controls the airflow to

the idle system. In addition, a diaphragm-guided linkage to the left-hand throttle valve was required in order to be able to constantly monitor and regulate the level of idling, controlled by two solenoid valves.

You know, of course, that the carburetor disappeared in an incredibly short time, although the ECOTRONIC still made it into series production. Perhaps a lesson for manufacturers who, at some point in the future, will be

relying on internal combustion engines for cars for a little too long.

|