Mechanical Charge 2 Mechanical Charge 2

Historically, Saab was once a forerunner of supercharging, at least when you look at the otherwise staid upper class sedan segment. It was considered to be risky for the engine at the time. In fact, they were thought to be

only for racing, not at all suitable for a family car. It seemed too rough and not very controllable for normal drivers to be able to cope with a winding road reasonably quickly.

In 1980 the injection engine was equipped with a turbocharger. This increases its performance from 87 kW (118 hp) to 107 kW (145 hp). The company must put its products in a higher class given the prices. But the

possibilities of the four-cylinder beyond the two-liter displacement are limited, investments for a six-cylinder are difficult to represent. This is how supercharging led to this remarkable increase in performance for the time.

Charge air cooling was added in 1984, but the engines initially worked without a lambda-controlled catalytic converter. This then reduced the performance from 129 kW (175 hp) to 118 kW (160 hp). In 1987, a water and oil-

cooled turbocharger was introduced for the first time, and in 1989 a so-called 'soft turbo' without intercooler and APC system, with 104 kW (141 hp). A small turbocharger clearly avoids the turbo lag when accelerating.

The Automatic Performance Control decisively combats the problems of the time with supercharged petrol engines. Their compression ratio had to be lowered to avoid knocking. But if you drove in

areas without full supercharging, the power and torque yield was lower than with the original naturally aspirated engine. In 1982, Saab came up with a system that, in principle, could be driven with a higher compression ratio,

e.g. of 8.5:1 instead of 7.2:1.

The secret lies in the intake of important parameters, e.g. primarily the boost pressure and the temperatures. Quite new was the knock sensor in the engine block, which, instead of normal vibrations, transmitted the changes

caused by knocking combustion to the control unit. The wastegate was no longer connected to the boost pressure via a vacuum actuator, but was controlled pneumatically and electronically. So afterwards even 9.0:1 was

possible with boost pressure always finely regulated along the knock limit.

First of all, this solved the problem of operating areas that were disadvantaged in terms of performance. But with the catalyst came new hurdles. Because while the compressor does not intervene in the exhaust gas area at

all, the exhaust gas turbocharger ensures that the exhaust gases relax to a certain extent when leaving the turbine. The catalytic converter didn't really like that because it needed the full heat of the exhaust system to reach its

start temperature.

On the other hand, the problem was where to put the heat from the turbo itself, which Saab had already encountered with water cooling. In view of the lambda-controlled catalytic converter and the now slowly gripping

CO2 regulations, turning the mixture screw was not a tried and tested method. Evaporating fuel is so effective that, for example, these insanely powerful engines used in the American acceleration races, cooling

by air or water is completely dispensed with.

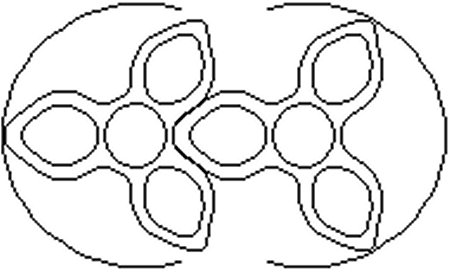

Finally getting down to truly mechanical turbochargers, simply denoted by the letter 'G'. 1987 in a small series, from 1990 then as models G40 and G60 can be ordered normally. It's a shame about the vehicles, because they

received an unbelievable boost in performance, even in the lower engine speed range. We will devote a separate chapter to the G-turbocharger. Here only so much: It is an impressively beautiful principle, unfortunately not

well managed in practice and therefore quite prone to wear and tear.

|