|

Lithium Lithium

It is a special element in many ways. Not only does it have the lowest density, but also a high willingness to combine with other elements. Even the demand forecast for 2025, i.e. for all batteries, accounts for almost 0.5

percent of the currently assumed reserves. Like cobalt, by the way, lithium is not one of the rare-earth elements that are so often mentioned.

The largest producing countries are Chile and Australia, although most of the reserves are believed to be in Bolivia. Overall, however, the same situation as in the previous chapter, the numbers cannot be trusted, but one

thing is certain, there is enough lithium available. The concerns about the type of mining are much greater. With cobalt it is child labour, with lithium it is mainly water consumption.

Overall, however, only a good third of all batteries manufactured are involved in the extraction of lithium. To name just one sector, the production of glass and ceramics add up to a quarter of the total extraction. And if you look

at the third for batteries, only about two-thirds of that is for electric cars, and half of that again is for public transport and hybrid drives, which some electric car fans say we should avoid.

In summary, only just under a third of a good third remains for pure electric cars, i.e. a sixth of total production. And anyone who is still too lazy to connect their hand drill to the socket is of course also included in the statistics,

as are computers and telephones, which together make up a significantly larger share than electric cars. Of course, their share will increase in the coming years.

Lithium, for example, is mined underground in Australia and above ground in Chile, which already explains well over two-thirds of current world production. In South America, half of the world's production, if you include

Argentina, comes from salt lakes such as the Atacama Desert in the middle of northern Chile. Just as with cobalt, lithium was not the main product of mining for a long time, but with salt lithium, potassium, magnesium and

boron were extracted as by-products.

In the meantime, of course, the order of interest has changed. So now it's getting tricky again, because the Tesla fans are back at work. They convert the water consumption from the often quoted 2 million liters of brine water

(not drinking water!) to the particularly high proportion of lithium, especially in Chile and in a daring comparison come to the same water consumption in the production of a Tesla battery as by almost two kg of beef.

Whether that's true or not, more moderate water consumption would be good for the environment there and would also be possible through better distribution, e.g. to Bolivia, which hasn't really started with mining yet. Here,

politics would be even more required than with the charging stations. We certainly cannot do without lithium. It is probably also planned for the next generation of batteries, the solid-state battery. But there will still be many

mining areas. Again a figure of Tesla fans, allegedly there is even lithium for 10 million electric cars in Germany.

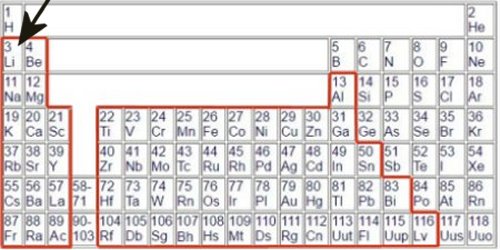

| Lithium | -3,05 V |

| Potassium | -2,93 V |

| Sodium | -2,71 V |

| Magnesium | -2,36 V |

| Aluminum | -1,67 V |

| Tin | -0,76 V |

| Chrome | -0,74 V |

| Iron | -0,44 V |

| Nickel | -0,25 V |

| Lead | -0,13 V |

| Hydrogen | 0,00 V |

| Copper | +0,34 V |

| Silver | +0,80 V |

| Platinum | +1,20 V |

| Gold | +1,50 V |

Not only the arrangement at the top of the electrochemical voltage series, which identifies it as the basest metal of all, can prove the special position of lithium. We compare with the 1.75 - 2.4 V of a lead acid battery and the

1.5 V of the mini batteries with which we are used to handling. The former has a nominal voltage of 2 V, with the lithium-ion battery it is around 3.6 V, with the charging voltage being up to 4.3 and the final discharge voltage

being 2.5 V (significantly higher in electric cars).

|

|