Rebirth of the solenoid valves

No, we do not really want to reprocess the history of the solenoid valve injectors from Bosch, although up there quite a few are assembled. Behind the Common Rail Injector you may rightly

suspect the series and behind it the abbreviation for the injection pressure. The trace back here recognizable to 500 bar, perhaps at the first versions even lower. Right and up then matching rail and pump.

We present this history here, because it was an endangered species in the meantime. Because with the appearance of the piezo injectors

2006, hardly anyone granted the injectors with solenoid valves a chance for the future. All the more interesting that Bosch provides a solution 2009 that the more cost-effective system with solenoid valves makes

competitive again. Bosch produces, incidentally, since then both systems depending on the cost pressure (Video 2).

Piezo switches faster and is able to close against the high injection pressure. At solenoid valves exists still a difference between the opening pressure at the bottom of the pressure shoulder and a well-regulated

counter-pressure acting from above of the needle. Therefore, solenoid valves must work only against the pressure difference and that obviously takes too much time when it comes to fractions of milliseconds.

The solution at the first CRI2-18 was simply another form of the closing valve. Have you perhaps already been thinking about the intake/exhaust valves in the engine? They're obviously designed in such a way that the

compression pressure helps to keep them leakproof. Also here has been attempts, for example, with sliding sleeves and at the channels of the two-stroke engine with rotary vanes. Has not been prevailed, presumably

because it is about the sealing of gases.

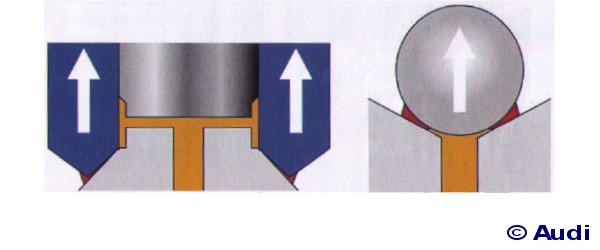

Today one is much more advanced with regard to the precision and after all, to seal is 'only'

fuel. A sleeve as a valve (picture top left) can be opened and closed nearly independent of the pressure as opposed to a ball valve (pictured top right). If then the sealing surfaces are correct, is there perhaps still a little

leakage compared to the part on which the sleeve is moved. Because a pressure difference is no more switched, there are no two different areas of different high pressure above and below what the possible leakage

restrains toward the central part. Bosch calls this 'pressure compensation'. Today one is much more advanced with regard to the precision and after all, to seal is 'only'

fuel. A sleeve as a valve (picture top left) can be opened and closed nearly independent of the pressure as opposed to a ball valve (pictured top right). If then the sealing surfaces are correct, is there perhaps still a little

leakage compared to the part on which the sleeve is moved. Because a pressure difference is no more switched, there are no two different areas of different high pressure above and below what the possible leakage

restrains toward the central part. Bosch calls this 'pressure compensation'.

| Undivided magnet armature, high pressure from top up to bottom |

The success is astonishing. The manufacturer indicates the possibility of up to eight injections, the pre-injection with very little temporal distance to the main injection possible. 11/15

| 1 | Dosing unit |

| 2 | High-pressure pump |

| 3 | Fuel filter |

| 4 | Electrical pre-feed pump |

| 5 | Pressure control valve |

| 6 | Non-return valve |

| 7 | Rail |

| 8 | Rail pressure sensor |

| 9 | Solenoid valve injector |

| 10 | Sensors |

| 11 | Actuators |

| 12 | Low pressure |

| 13 | High pressure |

| 14 | Return flow |

| 15 | Electrical line |

| 16 | Control unit |

|