Atkinson/Miller Atkinson/Miller

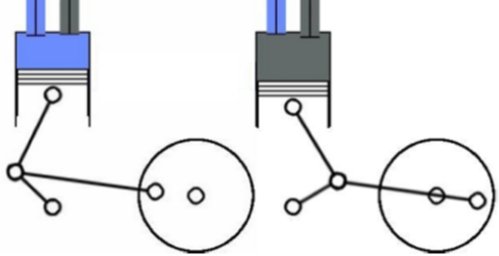

The diagram shows the significantly more complex structure of a four-stroke engine based on the principle invented by James Atkinson in 1882. The crankshaft, which then transmits the torque to the clutch or

transmission, was located to the right of the actual engine.

The Atkinson principle becomes clear when you compare the higher position of the piston at the end of the intake stroke (left) with the lower position at the end of the power stroke (right). This complex

mechanism results in a lower compression ratio compared to the expansion ratio.

So if you take a certain path of the piston for compression as given, the same piston's path during the power stroke is longer, meaning the bottom dead center is positioned lower. The (new) crankshaft pulls the

lower end of the connecting rod more strongly to the right than it previously pushed it to the left.

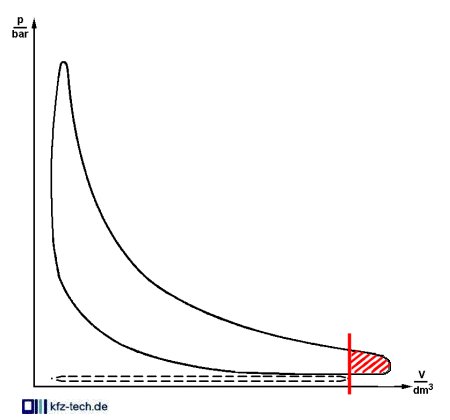

And why do we do this? It's about using the energy of the burned gas for longer and thus more efficiently. The diagram above clearly shows the longer stroke during expansion compared to the shorter one in

the charging loop below. It's the residual pressure at the end of the power stroke that acts on the piston for a slightly longer time.

As a result, the exhaust gas enters the exhaust port at lower pressure. Better utilization of the fuel's inherent energy saves fuel. When the diesel engine was invented, the principle was considered feasible for

this engine as well. However, it never became widespread in either engine type due to the complex crankshaft drive.

Ralph Miller's engine concept, for which a patent application was filed in 1947, used Atkinson's principle without its complicated design. Toyota was the first company to truly bring this principle to fruition.

Initially, the goal was not to lengthen the expansion section, but to shorten the compression section.

This can be achieved much more easily through valve timing, namely by closing the intake valve later. Unfortunately, this is often presented as if lower compression is exactly what humanity has been waiting

for. However, even less talented tuners could tell a thing or two about the increased performance achieved through higher compression.

Higher compression -> lower consumption

and vice versa. |

How was the conflict resolved? Looking at the data for the Prius II, you discover, in addition to variable valve timing, a compression ratio of 13:1, which was already a novelty for the time around 2000. From now

on, at the very latest, one must separate the actual compression ratio from the geometric compression ratio. So, the figure seems to refer to the former.

This means the engine still reaches its knock limit, even if some compression is removed. However, it does not reach the full possible filling in this case of an engine with a displacement of 1.8 liters. This

allows the combusted gas to expand in the cylinder for longer than in a normal engine of this size.

However, it seems sluggish in areas where it operates with a smaller displacement. This is where hybrid technology comes into play, with its electric motor enabling it to achieve a sportier or more normal

driving style. More effective, but even more complicated, is the variable transmission ratio between the combustion engine and the variable drive, which eliminates the need for cumbersome downshifts.

It's even possible to partially forgo the enrichment of the combustion engine, which has otherwise accompanied this engine type almost since its inception with every acceleration. And then there's the variable

valve timing, which can restore the engine's performance at full throttle, for example. Then, of course, the phase of low consumption comes to an end.

But that's not how you drive a Toyota Prius. If you stay moderate, the Atkinson/Miller concept makes a significant difference compared to gasoline-powered counterparts, something you'd normally expect to be

the opposite, given the larger mass of a hybrid drive, for example, on the highway.

| Incredibly high level of regulation . . . |

In addition to the longer expansion during the power stroke, two other elements brought the Atkinson/Miller principle to the attention of engine builders: the variable valve train and the associated change in

compression during engine operation.

Then came hybrid technology, whose electric motor helped the combustion engine escape the lower rev range in a somewhat sporty manner, despite saving fuel. It's questionable whether the longer expansion

represents the main contribution to the savings, or whether this contribution merely lends the whole thing the names of its two inventors.

There have also been efforts, e.g. by Mazda, to bring variable compression a little more to the fore by bringing the principle closer to the diesel engine. Not entirely unjustified, as long as one doesn't refer to it

as a so-called 'compression ignition' and calls the engine as 'DiesOtto'.

No, the spark ignition remains. A relatively new feature is the ability to regulate near the knock limit, where significant savings potential could have been achieved had e-mobility not (presumably) halted all

further developments of the combustion engine. It's important to note that development times here are considerably longer than for car bodies.

Almost all previous attempts, such as the mechanical method of changing compression while driving, have revealed adventurous possibilities. Saab wrote at the time that compression ratios of up to 26:1 were

considered possible with a cold engine. And the variations within the operating conditions of a warm engine are presumably also diverse.

However, knocking combustion requires swift action, and that's likely only the ignition system can do. This means that the knocking must be stopped immediately by adjusting it in the 'late' direction and, of

course, must not significantly increase fuel consumption. The valve timing then follows suit as quickly as possible.

|