Sensors - Potentiometers Sensors - Potentiometers

What do you think my colleagues and I did first when we were training on the first e-gas on a Peugeot? You can not get on it? We looked at the gas pedal and searched for the plug. We deducted it immediately while the

engine was running. You can guess what happened then. Immediately the resolution comes.

We often allowed ourselves such seeminig stupid things. On a Porsche with K-Jetronic, we sawn off an injection valve at the front and put it back in place. Why? Because the trainer had claimed that the valve would not

affect the amount of fuel injected. Yes, it did not, but only with the K-/KE-Jetronic.

At Renault we drove the brakes hot on a Megane folding convertible and then parked it after operating the then new electric handbrake. Then we listened intensively to the rear wheels and indeed, after a certain time, the

brake was extra tightened, even though the car was long abandoned and the doors locked.

And the Peugeot engine? No, it did not stop running, on the contrary. It immediately took a certain speed significantly above the idle. That would be enough to get home or to reach the nearest workshop. The speed

could of course only be changed by switching different gears.

No, actually, this chapter is not just about the electronic foot pedal. Incidentally, this is also because those foot pedals of the newer generation no longer necessarily contain potentiometers (picture above). Just look at

the last video below. It's about a non-contact, working with the targeted detuning of magnets.

Also, in this video, the American tragedy of allegedly defective pedestrians is being investigated, which in driving position did not return to idle. Perhaps a fault of the insufficient training of the driving students in the USA,

because a determined, not lessening kick on the brake in any case forces a combustion engine even from full load to a full stop. Turning off the ignition helps.

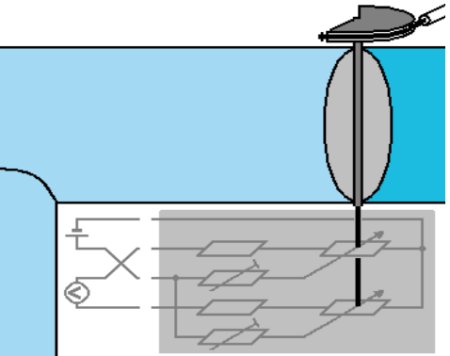

Older foot pedals usually have potentiometers that tell the engine control unit about the accelerator pedal position. There are always at least two for security, may be one with increasing and the other with decreasing

resistance when accelerating. The voltage behaves inversely porportional to that of the resistance. In other versions both work in the same direction maybe with a certain distance in the resistance.

In any case, the accuracy does not increase, if one adds to a measuring device, a second with the same accuracy. For example, the average between two clocks can only be more accurate if one is faster and the other

is slower than the correct time. But do you know that? But if both go faster or slower, only one of them is more accurate if you take the average.

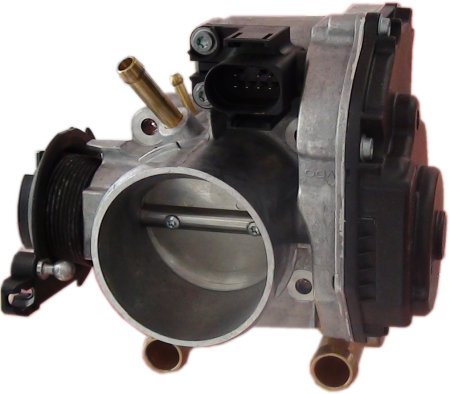

| Cable with throttle and potentiometer |

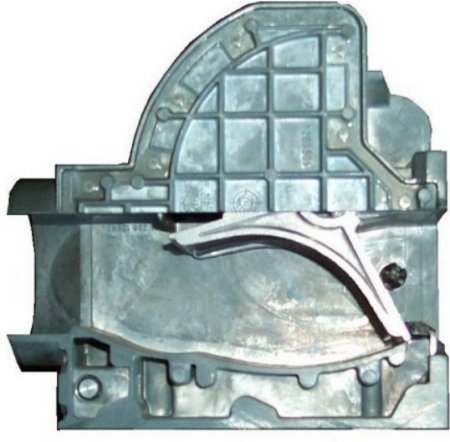

In our case, resistance is likely to be linearly increasing or decreasing. This does not have to apply to every potentiometer. Measure once an old air flow meter (picture below) and you will be surprised. Also, a double

potentiometer is not only on the (older) electronic foot pedals, but also on the throttle, be it by throttle cable (picture above) or actuator operated.

Non-contact measurement is superior to resistive tracks. In case of a defect of one, the control unit takes the second one and/or goes into emergency mode. But what does a defect mean in this case? Each

potentiometer has three terminals, power supply and signal line from the resistance path traversing grinder(s).

Of course, now you can perform a resistance measurement without voltage or pick up the voltage signal given to the engine control unit. Only this will not localize one of the mostly produced damages in by lasers

resistance tracks. However, at this occasion you can compare setpoint and actual value.

| Motor driven throttle with potentiometer |

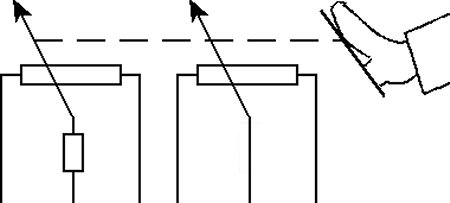

That's the failure within a very small distance. So unless you accidentally catch the point of failure with the accelerator pedal, you have no chance. Therefore, choose the right measuring device, namely the oscilloscope.

This will show you even the smallest dropouts, if you choose the x-axis for a long time set milliseconds.

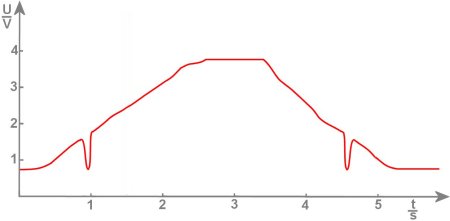

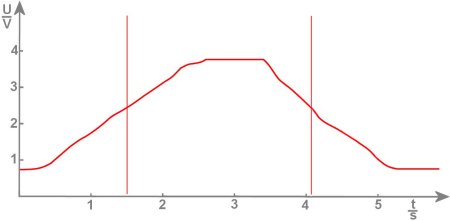

Here you can see the two possible pictures of the measuring process at one of the potentiometers. For this, the pedal was pressed slowly and withdrawn just the same way. The top picture shows a major defect at 1

and 4.5 seconds. You could have found that with the multimeter as well. But it would have been much more difficult to discover the small damages after 1.5 and 4.1 seconds on the picture below.

|