Tires 1 Tires 1

The tire is first assembled and then baked together. This is where the rubber-coated substructure of the tread and the core are created, from then on called the 'bead'. Both are connected as a carcass by the side walls

provided with several layers of fabric. The tread finally encloses the steel part of the tire.

With the softer sides, the tire's cross-section largely follows the relative flatness of the tread. The carcass has to withstand the high pressures, e.g. 8 bar in commercial vehicles. While the steel threads form a rather small

angle, the fabric made of steel cord is at an angle of approx. 90° to the running direction, hence the name 'radial tires'.

The designation 'belt' is more likely given by the steel-reinforced tread. It largely determines the properties of the tire, although the rubber compound plays a role that should not be underestimated. The profile, on the other

hand, tells us a little about the purpose of the tire.

If it has coarse treads and a strong transverse profile, it is more suitable for winter conditions and terrain. With finer transverse grooves, it drains the water better than summer tires, while longitudinal grooves emphasize

straight-ahead driving properties and tracking. Nevertheless, the tire remains a product entrusted with a wide variety of tasks.

They are so important, e.g. for driving safety, that manufacturers of large series constantly place orders with several tire manufacturers in order to be able to get rid of the maker that least keeps up with the ongoing

development. With tires that are no longer up to date, the entire product often suffers.

Not only objective tests are possible. But even here there are differences when running in a huge drum or in the road test. In addition, test drivers are asked to give their opinion more than in other areas. The tire is one of the

parts of the vehicle that most drivers form an opinion about.

Even in the early stages of development, there were around 10 criteria by which tires were judged. Due to higher demands on comfort, safety and recently also smooth running, this number has risen significantly, of course

all with the greatest possible operational reliability.

In the process, the requirements quite often get in each other's way. The tires, which still show a certain readiness to drive despite the loss of air, are a thorn in the side of advocates of more comfort because of their

reinforced sidewalls. Likewise, the smooth running that are procured the tires can have an unfavorable effect on braking behavior.

Sometimes tire problems are attributed to a whole system. For example, the steering of vehicles with a sporty touch is subject to more scrutiny. The test engineers then have to find out whether the negative symptoms can be

remedied by choosing different tires.

Even the environment participates in collective criticism of the properties of tires after the other components have become significantly quieter, e.g. the power train. The tire/road combination is often almost the only thing that

can be heard on the highway. Sometimes people try to avoid expensive noise protection fences by changing the road surface.

Incidentally, the still rampant tendency towards wider tires also tends to contribute to more noise. Lately, one has the impression that thereby attention to the durability of a tire has fallen by the wayside.

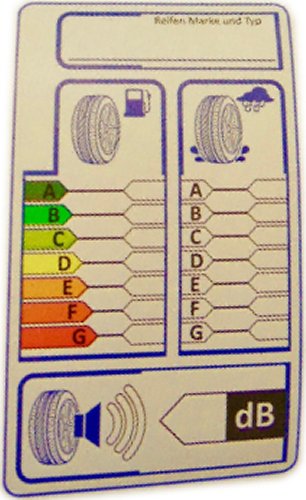

Consumption, wet grip and noise seem to play the main role (picture above).

|