Physics - Friction 2

We can't help stuffing as much automotive technology as possible into the subject of friction. So before we turn our attention to the physical phenomenon of friction, here is another, completely unexpected aspect. This is

where a part of the vehicle comes into play, where friction is only suspected in connection with the windscreen wipers.

It's about the wear and tear on the windshield. Yes, it suffers because it is exposed to constant bombardment over thousands of kilometres, which could easily be described as sandblasting. In addition, there are

somewhat larger parts that cause corresponding damage. And just as water carves river valleys into mountains over thousands of years, the material glass, despite its hardness, is not immune to punctiform erosion.

| Polishing agents seem to be of little help. |

Although it is hardly possible to make any general statements, quite a few experts advise after 100,000 km to replace or at least to have a closer look. This also includes the windscreen wipers and especially their resting

or turning points. What can happen? This is best answered in the dark, with oncoming vehicles. If you can see their details clearly and distinctly, then there is usually no need for action.

But woe betide the boundaries and the windscreen wiper adds its streaks in light rain. What's more, even new headlamps then only retain their perfect cleaning effect for a short time. Because a damaged windshield of

this kind naturally causes serious damage to the rubber immediately. These are two reasons, enough to have the windscreen replaced.

So don't be sad if after a certain period of time your windscreen is hit by an unknown object and thus has to be replaced, usually at the (partial) cost of insurance. Because you will have to pay for one of the above-

mentioned changes completely yourself. But what good is the best LED or even laser light if you don't perceive the foresight illuminated in this way from the inside at all.

Friction is an issue almost everywhere on the car. You will probably already have experienced how quickly a scratch in the paintwork can spoil the pleasure in your vehicle. And either it was another car, or nobody can

remember from those who shared the car. It's no use either, because the loser of this thing has already been determined: the one or the one it bothers most, probably you.

In the past, there was only one method, namely partial painting. Grind the affected component to suitable edges, mask it accordingly, possibly even fill it wet on wet, paint on it and sometimes even clear coat on top. Today

there are so-called paint doctors for this. Whether also female doctors, unknown, inflation of the term 'doctor' included.

For example, a paint repair is carried out between two rentals of a rental car company in just under two hours, because for certain customers the failure of a car may be more expensive for the lessor than a quick repair

and, perhaps even more serious, it may have a bad reputation. And the repairman usually has everything necessary with him.

Of course the RAL standardization helps to limit the number of colors. As far as friction is concerned, nowadays there are incredibly fine sandpapers, but also liquids for working with the polishing machine, which has a

similar effect. It is about creating a base on which to hold what is necessary to make the repair site invisible. Of course, chemical dissolvers can also be used for this purpose.

Deeply work cracks and reconnect them, plug holes, quick drying through targeted heating and grinding again and again. With sheet metal it is often enough possible without any additional material, only by very skilful,

selective pushing back. But that is beyond the scope of this book. Just like the gluing, which has long since taken its firm place in motor vehicles.

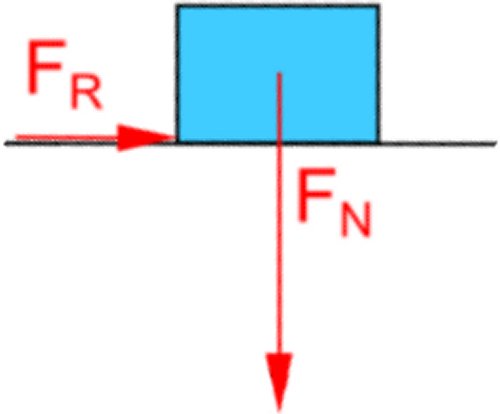

The picture above shows, among other things, that the force pushing the block is usually smaller than the normal force resulting from its weight. Thus the dimensionless friction coefficient μ is usually smaller than 1,

only when glued it grows far beyond 1. Just look at the sloping positions at a motorcycle GP. There the picture at the top is still harmless against.

| Probably more adhesive than frictional connection to the road surface - slicks |

It cannot be high enough for the motorcyclists in the curve. But if you are pulling a heavy object, it should be as small as possible. With infinite delicacy there is still something to be observed: The transition from a resting to

a moving object is much more difficult. And this is exactly the difference between sliding and static friction.

Whether you can use it while driving. Sure, it doesn't have a huge or even measurable effect, but you can try to drive towards the end of a traffic jam in such a way that it moves straight on as you arrive, so you don't have to

stop. Then you would have avoided static friction. But be careful, there might be people behind you who don't know anything about this physics.

The difference between static and sliding friction is only about 10 percent for steel on steel, and a little more for steel on wood. But if there are such differences, it means that once a V-belt starts to slip on the pulley shown

above, it will continue to slip unconditionally. You have probably heard a car screeching in this way before. Be sure, the V-belt was no longer sufficiently tensioned.

The V-belt itself is a clever construction. If the V-belt guide deviates from the vertical by almost 20° on each side, approx. three times as much torque can be transmitted. The further development is the so-called flank open

V-belt (picture above) with almost the same good grip due to filling the gaps in the pulley with considerably less wear.

The preliminary end of the development shows the belt drive with even less abrasion and good efficiency with very good adhesion, usually also with long service life due to special precautions for constant tension.

At the end of this chapter an example for the form fit: If we stay with the belt drive, then at this point we should mention the toothed belt (picture above), which has undergone a remarkable development. The shape of his

teeth has long since adapted to his needs. Its service life over far more than 100.00 km is remarkable. Even the wheels on which it runs can deviate from the pure circular shape during one revolution, depending on the

force required.

|