Physics - Hydraulics 4 Physics - Hydraulics 4

This is a simple system that is intended to show how hydraulics can regulate itselve. One speaks of an open system and means, for example, the oil pan at the bottom into which the hydraulic oil flows back almost without

pressure. The pressure must therefore be generated anew by the oil pump each time. In a closed system, the pressure of the returning oil can be used.

In this case, the oil pump is a gear pump which cannot generate high pressures, but in contrast to a piston pump, for example, it generates a continuous volume flow. The pressure is generated externally between the

tooth spaces and the wall, whereby the return path for the oil is blocked by the teeth combing together.

Because of the connection between the two gears, only one needs to be driven. The left one runs clockwise, the right one in the other direction. Excessively high oil pressure, which could be caused by stiff oil in very cold

conditions, for example, and which would destroy the pump and/or drive, is avoided by a pressure relief valve on the left above the pump, which is set by the spring pressure accordingly.

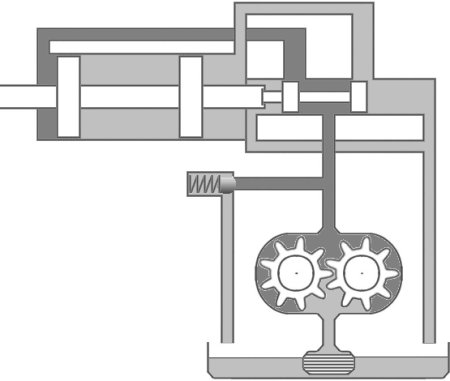

The picture shows only the drive unit e.g. for a table, which is currently in a position furthest to the left. If you follow the darker displayed pressure, you will see that the pressure regulated by the control unit in the middle

above the pump is already trying again to move the working piston to the left of it and thus also the table to the right again.

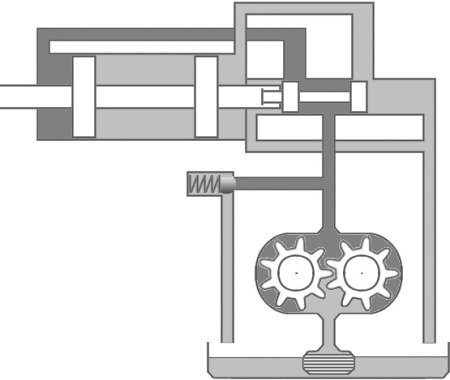

Here is the picture where it has already managed to do this quite a bit. This has no effect on the control system, which stays where it is and has ensured that the pressure has so far only been able to reach the working

piston via the upper left line. For the further events we must additionally assume that working piston and table have reached a certain speed and thus form a certain mass.

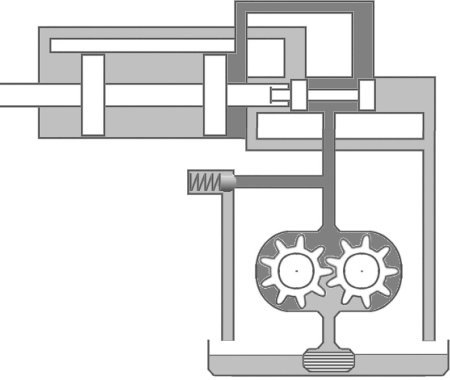

The pressure building up on the right beyond the pure pump pressure has slowed down the movement of working piston and table. So this here is the outmost point, which both can reach towards right side. This depends

on the pressure conditions, but even more on the free movement resulting from the sleeve-like connection between the working and control pistons. This is determined by its length, which distance the working piston and

the table can cover without moving the control piston with it.

So here also much more free space would be possible, which would extend the length of movement of the table considerably. In normal operation, without any electrical control of the hydraulic currents, there would be a

permanent back and forth movement.

|