Car-Technology: Engine Control 1

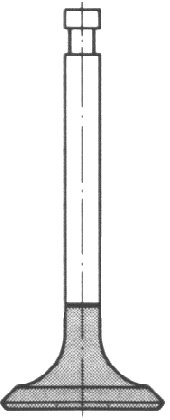

Let's talk about valves. No, not just like the one pictured above. A common definition for a valve is that it can close or open a pipe. In contrast to this the nozzle (e.g. in the carburettor), which has to be open all the time and only

reduces the opening cross-section.

We should try to mention as many openings of the cylinder chamber to the outside as possible. The first things that comes to mind are the ports in the two-stroke engine, although there are also such engines with at least

exhaust valves similar to those above. The ports are generally opened and closed by the piston.

But in principle a slide valve can also do this, at times e.g. in racing engines several cylinders of the row at the same time instead of throttle valves. It can also be designed as a rotary valve. However, when it comes to

tightness in relation to compression, all slides have their problems.

This is the great advantage of valves normally located in the engine. If you take a closer look at them, you will see that there is a certain correlation between tightness and pressure. is present. The higher the pressure, the

more the valves are pressed down on their seats.

Perhaps that is why they have survived until today. Without pressure out of the combustion chambert they are initially pressed onto the seat by coil springs, sometimes two per valve. Whether this has a positive influence on

the closing or the safety of being hit by the piston when it stays open?

By the way, there are also piston engines with enough space for a valve that is still open. However, the compression ratio cannot be particularly high here. The lower part, which actually seals the valve, is called the plate. the

upper shaft. In very old engines, they could also be arranged the other way round next to the cylinder.

If the plates of the exhaust and intake are of different sizes, the latter are usually larger. Overall, the feasible size of the plates depends on their number per cylinder and its bore. A little more opening is still possible through a

larger angle between exhaust and intake. All in all, the inflow ratios are very important, especially in sporty engines.

It is difficult to estimate the temperatures of valves, of course mainly at the plate. Common temperatures reach a maximum of 800°C at the outlet and 500°C at the inlet. Valves can literally burn. In the process whole pieces

may break off the plate. This happens when they cannot return to their cooling seat.

In the past, this was often enough an adjustment error. It was even possible that there was play in the valve train when the engine was cold, but this disappeared completely due to the different expansion coefficients of the

individual components involved. This was due to the different coefficients of expansion of the individual components involved, which disappeared completely when the engine warmed up and a thin, insulating air gap formed

between the valve and the seat.

Today's hydraulics, which provide for self-adjustment of the valves, are usually designed in such a way that if they fail, the valve remains closed rather than open. This behaviour is also the reason why in the event of a lack of

compression, we should not always look for a loss of pressure but also for a possible lack of filling.

As you can see, this is a very critical point, the one between the valve plate and the seat. This is almost always made of a harder material than the cylinder head and shrunk into it. This is also done if you want to run a vintage

car on unleaded fuel. For the designs without valve seats, the lead had some protective effect.

.

The area of contact is so critical that not only is the angle prescribed, but practically its size. One can either increase the size of the contact area at the shrunken seat by seat angle, or reduce it with a significantly smaller or

larger angle above or below.

The shaft is usually also made of a different material because it is stressed in another way than the plate. Its possible problem area is the bearing in a bronze bush and the sealing above it. Often enough the latter had to be

replaced in the past because it was leaking engine oil from the cylinder head preferably into the intake tract.

However, the work had the advantage that with sufficient pressure through the spark plug hole, the valves could be kept closed despite disassembly of e.g. the springs and thus the replacement could be completed. Also

broken springs could be replaced in this way, if there had been no collision with a piston. This can be checked by inserting a camera into the combustion chamber.

Dismounting a cylinder head has become more and more complicated over the decades. Once it is out, the tightness of the valves can be checked by turning the head over and filling the spaces with liquid. On the other

hand, checking the clearance between the stem and the guide is a little more complicated but worthwhile.

Is that it? The number of valves is still missing. With three valves, there are usually two smaller intake valves and one larger exhaust valve, because the former only takes in air, which is more tedious than releasing pressure,

which is why there is more support here from a larger cross-section.

Four valves are actually the norm today. If you try to draw several as large as possible circles in a circle, you will quickly find that the best result can be achieved with four of them, even if the inlets are slightly larger than the

outlets. The arrangement of the spark plug is also ideal, more of a problem with two- and three-valve engines.

There were also five valves per cylinder. At least it was managed to control three intake valves through one camshaft. The end came when petrol engines were also equipped with direct injection and the space for the injector

and spark plug became too small.

Below is a soothingly simple video on how to grind in the valves. Much fuss is made about cleaning the valves. But the problem has largely been solved with only direct injection. If there is a lot of sticking, then it's probably oil

and further checks are definitely called for in the direction of crankcase ventilation,

.

|