Fuel delivery

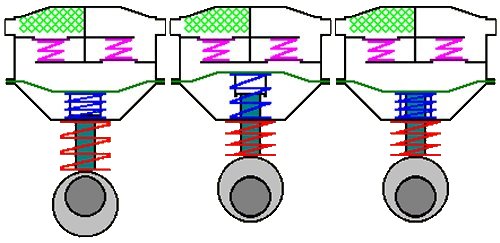

BDC TDC delivery TDC zero delivery

Yes, the carburetor belongs in the book on motor vehicle history. But the promotion of fuel should now be an issue here, not from the historical side, but from the difficulties in operating vintage cars. That comes from their

erratic existence, long downtimes and then they are suddenly supposed to shine at some concours far away. Apparently some of them don't want to go there at all.

We've reported many times about a stalling engine that required diving to the reserve valve while driving. And woe betide, the was already or still on reserve. No, in this chapter we are concerned with the construction of the fuel

supply and the elimination of weak points. It should be avoided that the concours is not reached on time with black hands and/or at all.

In the classic car there is one main enemy, components in the fuel that clog the sieves. Such contamination can be caused by rust in the tank, for example. This is also possible with frequently used vehicles, but more likely

with old-timers with their long periods of inactivity. A good tip would be a completely filled tank before parking, with the fuel serving as corrosion protection.

Needless to say, there are other causes of clogged sieves, such as improper handling of compressed air when the lines are open, or a tank coating that is dissolving. A commercially available filter fitted between the tank and

the pump could make the contamination visible at an early stage and would also allow longer passage than the sieve directly on the pump.

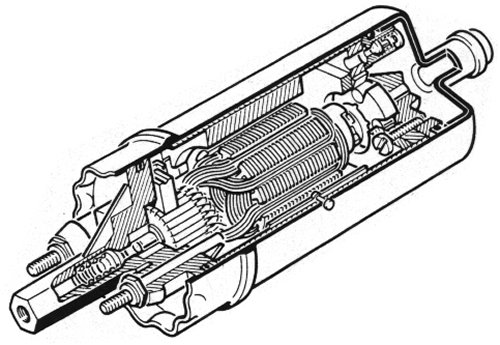

But the whole thing takes place in the suction line. Frequent checks would therefore be necessary, because mechanical pumps, and these have been discussed so far, can generate considerable forces. Unfavorable if a

clogged filter causes a high negative pressure and damages the pump. Not infrequently, diaphragm pumps driven by the combustion engine have even managed to significantly reduce the size of a tank when the ventilation

is clogged.

With that we would have already mentioned another possible error. As you might have guessed, trying to start without the tank cap will clarify this. By the way, modern tanks are of course made of a non-rusting material, e.g.

plastic. The membrane is inside the mechanical pumps and the electric pumps that were often installed in the past, e.g. in English roadsters. Of course it can tear. With a bit of luck you can see a trickle of fuel from the

ventilation/elimination of air of the space below the diaphragm.

How do you check a fuel supply? Because it can also be the drive, the cam could have worn down, there is an error in the further power transmission, one of the two valves could be stuck open or leaking. It's actually quite

simple: Operate the vehicle with the contents of the float chamber(s) and let the disconnected hose end in a container. You can calculate for yourself how much maximum fuel your engine consumes in the time stopped plus

a supplement.

While the valves on the float chambers can also impede the correct inflow in carburetors, this is different with electric pumps. In addition to a delivery rate of perhaps half a liter per minute, the delivery pressure must also be

measured. For this purpose, the circuit with the pressure regulator to the return flow should be absolutely complete. For vintage cars, maybe 2 to 3 bar is enough, for newer vehicles with petrol injection the pressure is higher.

If this pressure is not reached, or if there is no fuel at all, this may be due to the pump or its triggering. So it doesn't help, you have to go under the car if the pump is installed inline, remove the cover over the tank in case of

intank pumps. For the latter, please measure directly on the supply line to the pump, because there may be a control unit just before it.

It might not be totally crazy to always have a very long piece of single cable with you, e.g. from the house installation. It helps with all sorts of inconveniences, for example if you can lead it directly from the plus side of the

battery to the pump, of course with a fuse. Because sometimes only a very specific soldering point on the pump relay is defective. This and possible larger resistances in the line are thus bridged. Sometimes even a pump

that is actually defective gets back on its feet for a short time.

|