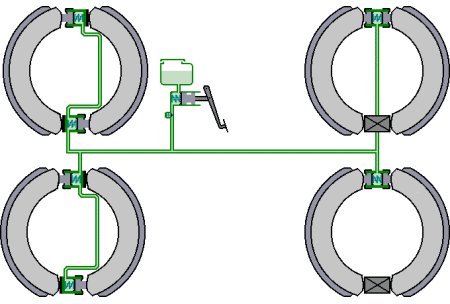

Hydraulic Brake - Single Circuit Hydraulic Brake - Single Circuit

This is the principle of the first hydraulic brake at all, but with a special feature. But more on that later. It is essential that a reservoir supplies the master cylinder with enough fluid (then often mistakenly called 'brake

oil'). When the pedal is not activated, the way must be free to all wheel brake cylinders.

Most importantly, this piping system may only be filled with liquid and must not contain air. Only this guarantees that the piston pushed by the brake pedal can transmit its movement directly to the wheel brake cylinders

and thus to the brake shoes.

Of course, the entire system must be tight, no brake fluid must be lost anywhere. Facilities of this type had no warning device. The only sign of a defect could be a softer and/or longer pedal stroke. However, even then

hurry was necessary, because, for example, acting on the rear axle, mechanical parking brake is an absolutely inadequate replacement.

So the biggest drawback of the hydraulic brake is already mentioned. One sees rather the advantage, if one thinks of the predecessor of this brake, the mechanical four-wheel brake, whose cables had to be

adjusted in short timescales. The hydraulic brake retains the ability to transmit evenly the braking forces to the wheel brake cylinders and thus the brake shoes.

But if, for example, they jam and thus experience much wear, it still leads to unilateral braking effect. But that's not the fault of the hydraulic brake. It remains undisputed that it is

always a special experience how precisely and without any visible delay liquid is able to transmit forces across even the widest and most complicated ways.

The problems only arise if you take a closer look. In principle, the pedal travel should depend only on the wear of the brake pads. To readjust this means that when the brake shoes are returned to their starting position,

the stop points are changed so that the jaws move closer to the drums, thus reducing the free travel.

On closer inspection and assuming uniform wear of all linings, so you could see their added wear on the liquid level in the refillable reservoir, how far this is already advanced. Of course, today's plastic ones are more

practical than earlier. Nevertheless, care should be taken when adjusting each individual remaining brake lining thickness.

Because even the difference between front and back is a natural one. Maybe not exactly in the rear-engined car, but for all the others, more and more braking power is needed on the front axle. Incidentally, this is

documented in our drawing above insistently by two additional wheel brake cylinder, but also have other advantages.

Now, on closer inspection, one might expect a piston in a cylinder, which is driven forward by a pedal pressure. In principle, one would not even need a reservoir if it were not, as the name implies, including a

compensation of the lining wear necessary.

Nevertheless, one could remain persistent and get along with only a single hole between expansion tank and cylinder chamber. However, this would have to be quite small, because their diameter increases the free

travel of the piston. Also, this would have to be placed in the release position immediately before this hole (ie to the right of it), so that the hole can be closed as quickly as possible and pressure built up.

No, that's not how it works, because you would not have considered the way back of the piston. Such a pedal must be 100% 'stuck' to the foot, so follow its movement 1 to 1. Imagine if the pedal came back after a

braking delay. How should then be a possibly directly following without irritation for the driver to be possible?

And, of course, the piston must return quickly to the pedal. Whether the return springs in the wheel brake cylinders will do so quickly remains questionable. Nevertheless, air must not enter the system during this

process. There are and were, above all, different ways of dealing with this problem; in this chapter we want to limit ourselves to one.

So we're not starting from an annular groove, but from a cup cuff. On this acts the return spring of the master cylinder. So it pushes them back after completion of braking, which dissolves it from the cylinder walls and

fills not fast enough from the wheel brake fluid flowing back from the rear area.

| Can you imagine that these outer sealing edges of the cup cuff fold back slightly when they retract,

thus releasing the fluid from behind? |

For this purpose, the piston on which the cup collar is applied during braking must have a number of holes. You can imagine that over 100 bar loaded rubber on a piston with holes is not a particularly successful

combination. Therefore, in between the so-called filling disc is installed, which forms a smooth bearing surface for cup seal and still ensures the flow of brake fluid.

In addition, a larger sized second connection to the expansion tank is necessary, which is called 'equilisation port'. And thirdly, the piston must be additionally sealed to the space of the piston rod, whereby we now get a

primary sleeve (primus - first) to the brake pressure and a secondary seal (secundus - second) to the other side.

Almost through the entire chapter runs the worry, the pedal travel to the brake response could be too large. In this context fits last as the pre-pressure valve in the outlet line. It allows brake fluid to pass unhindered

during the braking process, but blocks its retraction as soon as a certain, low pressure is exceeded. It thus holds a form to the drum brakes and promotes a certain slight concern of the brake pads. This also reduces

the response time.

Finally, take a look at the encoder to the left of the master cylinder. Here, from a certain pressure, a spring-loaded, electrically conductive plate is pressed onto two contacts and thus switches on the brake light. This is

also available as a contact switch on the pedal, but this is the better problem solution because it is directly coupled to the exporting brake pressure.

First post-war Beetles: Only simple taillights, Winker (black arrows) to the direction indicator and a central red brake light (white arrow) together with the white license plate illumination.

|