Compression 2 Compression 2

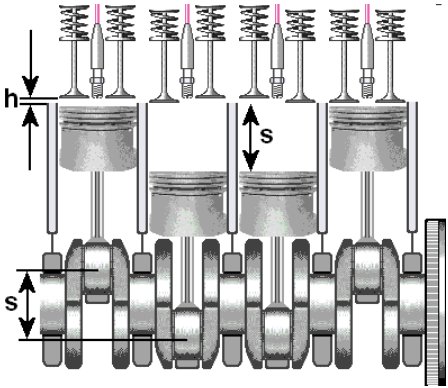

In view of our topic, supercharging, the question of what the compression ratio has to do with it is of course entirely justified. Before we answer those, we need to clear some space by calling the compression we've

discussed so far 'geometric'. It is simply the ratio of space before and after compression. It is a coeficiente and has no unit. That's why you write bashfully: '1' after it. But what does it say about the pressure conditions?

You may have guessed once again that if there is one geometric compression, there must also be another. Of course, namely the one caused by inflowing gases. No, this process does not always take place in the same

way, there are significant differences. It's not just about aerodynamics in the wind tunnel. This also happens in the intake and exhaust systems. In the past, significantly more power was achieved simply by relocating and

merging the exhaust pipes of individual cylinders. And if you do something similar on the suction side, you get more filling and therefore at least more pressure, which is also in the sense of compression.

Much of this is called dynamic charging, but we'll get to that later. Now you should first imagine this and of course 'real' supercharging and what it can do to an engine. Certainly nothing good, as we saw in the previous

chapter. So what do you do, you reduce the geometric charging when installing a turbocharger or compressor. If you compare modern diesel engines with older examples, you will find significant differences. At the top there

have been naturally aspirated engines compressed up to 24:1 and the first has just appeared with only 14:1.

But you mustn't draw the conclusion from this that the diesel engine has measured up to the petrol engine in terms of compression. Of the only two with this same characteristic, the petrol engine is naturally aspirated and

the diesel is supercharged. So it also has the higher compression here. A good example that geometric compression is no longer the only characteristic.

It's less dramatic with the petrol engine, but it doesn't have that much experience over large series behind it. And also a few other special features that do not let it to deviate hugely from the perhaps maximum possible

12.5:1. Sometimes 10:1 to 11:1 are still possible. The control electronics are obviously made in such a way that they deliberately allow the engine to run into the danger of knocking, in order to then control it out again after the

next revolution.

In accordance with what we learned above, the petrol engine runs best with the highest possible compression ratio. That's why there are differences in the modern Motronic between particularly quick and rather slow-acting

measures. You can imagine which of the two is required with an engine running at 6000 rpm and a mere 10 milliseconds per revolution. But when the slowest processor, a Commodore 64 from 1980, can process 1000

machine instructions in a millisecond, you can see how little the problem is for the electronics.

This is more difficult with the diesel engine. Here there is no such clear sign of a misdevelopment as there is in the petrol engine with the self-ignition. How do you plan to determine when the engine begins to feel

uncomfortable and then reduce the injection quantity next time? However, whether that is the reason for the much larger differences in the compression ratio between naturally aspirated and turbocharged engines remains to

be seen. However, whether that is the reason for the much larger differences in the compression ratio between naturally aspirated and turbocharged engines we will leave that to one side here.

In any case, they exist and they are meaningful for the charging system. For example, if you know that the first TDI engines from VW had a compression ratio of around 19:1, you can see from the current compression ratio

how much the supercharging contributes to compression. Because the engine builders will hardly do without the necessary compression, perhaps at most to achieve better NOX values. But that has to be

achieved differently the next time emissions legislation is tightened.

No engine builder is so misguided as to dispense with pressure in the combustion chamber in the long term. Especially since the ever stricter CO2 limits set certain guidelines for economy. This is not to say

that serious emissions problems can be solved by a single measure. It is usually a combination of measures. But the knowledge remains that the reduction in the geometric compression ratio can be used to deduce the

strength of the supercharging.

|