Mechanical Charge 1 Mechanical Charge 1

It's time to take a look at supercharging in general, without just looking at the exhaust gas turbocharger. In the case of the charge quantity, unlike the filling, the fuel share is included in any case. However, this only makes up

a small part in case of the petrol engine, because the 14.5 : 1 to be maintained at lambda = 1 are weight and not volume shares. In relation to that, the difference would be much greater and in the case of the diesel engine

with its much higher proportion of air anyway. And this charge is crucial for the peformance of the engine.

At this point you may notice a certain equivalence of more cubic capacity or more boost pressure, which can therefore replace each other. The third factor is the engine revs. For a long time, Europe saw itself somewhat

limited here, until the Japanese, of all people, with their strict displacement limits for small engines, showed that they can have a long service life even with a high continuous revs.

Honda then became famous with the first manipulations on the valve train, which made the engine both sporty and reasonably drivable in everyday life. The German manufacturers also use this for large engines. The high-

revving V10 from BMW is only mentioned here as an example, which also generated a wonderful sound. Supercharging seems to have ended this development quite strictly.

The compressor, which is the subject of this chapter, would presumably be associated with a high revs. But first of all, it should be noted that the rotation level drops with supercharging. At it you can see the enormous power

of supercharging, because it not only compensates the lower performance due to the falling nominal speed, but actually increases it.

Some speak of a second motor when supercharging. This is easier to prove with the supercharger, because if you turn it upside down and fire it with stored air (something like this now exists several times), then it is

perfectly capable of actuating a vehicle. In the case of the turbocharger, its function as a motor is somewhat more difficult to illustrate.

So then the first supercharged engine would have been an early hybrid. Although perhaps not so much the support for peak performance, but rather the support for the lower rotational-speed range, also known as 'torque', is

even more important for everyday driving. And this is where the mechanical charger can play all its trump cards. We'll find out what they are in a moment.

It remains the secret of the engine builders as to how they were able to achieve this plus in torque without a great increase in weight, e.g. in view of the performance data above of a Mercedes AMG 45. The diesel engine

partially exceeds the 200 bar working pressure now. And while early tuners could reasonably rely on peak load being used relatively infrequently, when there's plenty of torque available down below, things are different.

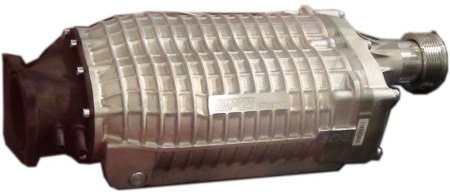

Here for comparison a Chevrolet Corvette Z06

And the power-to-weight ratio, or should one says better 'torque-weight', continues to rise. The latter in particular is rightly attested to have a lower consumption. The mechanical supercharging has the problem of the engine

power being tapped off via a belt drive. The consumption savings of the turbocharger are immediately believed, although its drive also devours engine power.

The mechanical supercharging must therefore prove that in the end there is an advantage in favor of lower consumption. Not only the mechanical connection to the engine speaks against it, but also the lower compression in

the case of the petrol engine. So it should actually use more. Nevertheless, it can score points, especially against an engine with the same performance but a larger displacement.

Especially when its displacement exceeds the limit of the sensible number of cylinders, e.g. has two more cylinders. Here you can grab the bigger losses with your hands. Which brings us to the opposite evidence of lower

consumption. Let's start with the significantly lower rpm level. When it comes to trucks, you fight for every 100 rpm less with which the can be moved on the freeway.

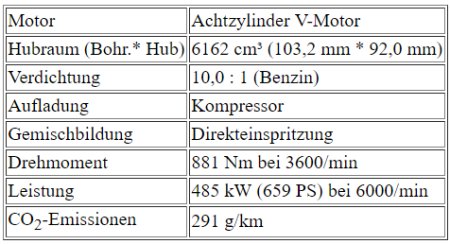

Let's look at the whole thing in the diagram. Below you can see the so-called shell curves. It is an attempt to show the torque and specific fuel consumption of a gasoline engine as a function of the engine rpm. Let's leave the

various power curves aside for now. The distribution of the highest torque can only be imagined here too. It would form the upper end of the shell curves with a maximum somewhere between 2500 and 3500 rpm.

So, now think that there is an accelerator pedal on the left. 150 Nm would then correspond to 100 percent accelerator pedal position, 100 Nm to 67 percent and 50 Nm to 33 percent. Whether that works out exactly like that is

not so important now. The five curves going up from the right indicate the power that is now required of the engine to overcome normal driving resistance and, for example, to cope with a slight increase.

The formation of the power curves is explained in chapter 'Measure 1'.

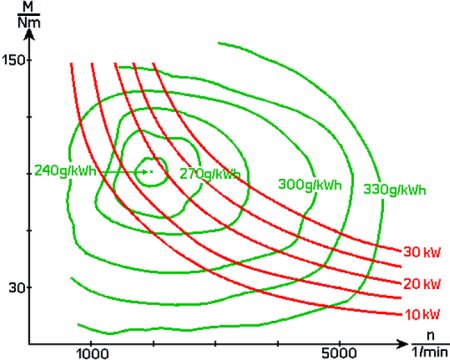

Let's say you need 30 kW, which can be activated at say 5000 rpm in second gear, 4000 rpm in third gear or 3000 rpm in fourth gear. Mind you, it is always the same performance. As you can see above, that results in either

approximately 315 g/kWh, 290 g/kWh or 275 g/kWh. On the y-axis you can see that from one gear to the next you have to step on the gas more and more in order to achieve or maintain the performance.

The difference between second and fourth gear is 315-275 g/kWh, i.e. 40 g/kWh. Multiplied by the same 30 kW, the result is 1200 g. Since a liter of petrol weighs around 0.75 kg, the saving between the two gears is exactly

1.6 liters, after all. This example shows that a higher gear brings advantages in fuel consumption, but also that higher engine torque is required for this. A sixth gear at around 1000 rpm would not have been possible in the

situation described.

Of course, it is clear that the rpm jump to the sixth gear is smaller, but this is about the principle. Especially from the point of view of charging. Because more torque in the lower engine rpm range can enable more frequent

use of higher gears, which in turn saves fuel. One could mention laziness in shifting gears as a small additional advantage, but this is no longer the case when high gears are consistently used.

Incidentally, the diagram above is from a naturally aspirated engine. With a supercharged engine, the steps of the shell curves would be wider with the same size designation, i.e. the consumption decreases less with the

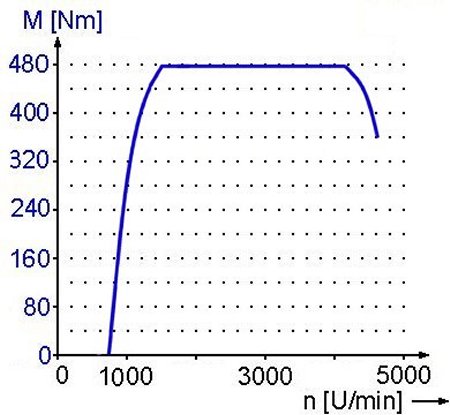

distance from the ideal point. In addition, the torque curve of modern turbo or supercharged engines is completely different due to their control behavior. Below you can see that of a turbocharged diesel engine with a torque

strictly limited at 480 Nm.

|