The above picture shows us something from the long, long ago. This arrangement of pistons, con-rods and crankshaft has been around since the birth of the four-stroke engine, actually, it even goes back as

far as the steam engine. In fact, even in the atmospheric gas-engine there were variations of this type of power transfer. Nonetheless, also today (2012) the crank-drive is not just

a side-issue, e.g., if, under the heading Downsizing, the three-cylinder engine with acceptable running qualities is to be installed

in mid-size cars.

There have been any number of attempts to replace it, not only with the rotary engine. None of the alternatives could assert themselves.

This principle has got

something going for it, applying the gas-force to a piston moving up- and downwards, then transferring the forces to a rotating crankshaft. Indeed, it's the relatively complex movements of the con-rod which increase the calculation effort needed for the dimensioning of the crankshaft.

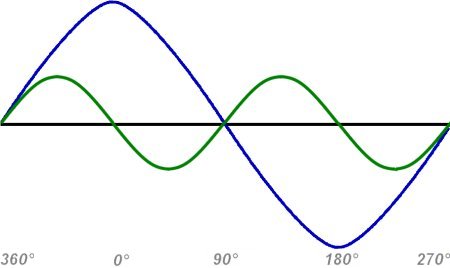

The first thing that comes to mind in this constellation, is the unfavourable mass compensation. Because the piston travels from top dead center (TDC) to bottom dead center (BDC) and back again, each half a

rotation contains a high mass-force towards the bottom and then back again. They occur once per crankshaft rotation, which is why they are called 1st order mass forces.

2nd order mass forces (shown here in green) can be found, e.g., in a V-Twin engine. In this case, the two pistons arrive at

their TDC at different

times. The occurrence of an upward working force occurs twice per crankshaft rotation. The angle φ (see diagram) that the crank-throw forms in relation to the perpendicular is particularly important, thus also,

marking the position of the crankshaft.

So, the rotating compensation shafts, which turn at twice the crankshaft speed, reduce the 2nd order mass forces. By the way, mass forces of a higher order are either disregarded or detected together

with those of the 1st or 2nd order (as a result) and possibly compensated for. There is no such thing as a perfect compensation anyhow. It's a miracle, that some engines run so smoothly,

so much so, that one has to place one's ear on the bonnet to hear them at all.

Also important for the smooth running of an engine, is the connecting-rod relationship λ. Thereby, the distance of the main bearing, from the center of the con-rod bearing r, is divided by the distance of the

center of the big-end to the center of the small-end. In the case of particularly long con-rods, this relationship is small, the engine runs more smoothly. However, this type of engine is higher and also somewhat

heavier.

A small con-rod relationship is more typical in older engines. Have a look at the length of the con-rods in the above picture. Modern engines allow the con-rods just enough length to keep the pistons, when at TDC,

away from the compensation weights. The disadvantages of the thicker walls and the higher piston- strain and friction are balanced out somewhere else. There are however, e.g., Daimler engines, which have the

same cylinder blocks but different strokes. In this case, the engines with the smaller capacity have the longer con-rods. 12/12